by Byron Laird | Mar 19, 2024 | News, Projects

FE Consultants (FEC) are proud to announce the success of our long-time client Hazer Group Ltd (Hazer) in producing first hydrogen and graphite from their Commercial Demonstration Plant (CDP) in Perth, Western Australia. The CDP takes Biogas from a water treatment...

by Sam Nicklin | Apr 22, 2021 | Projects

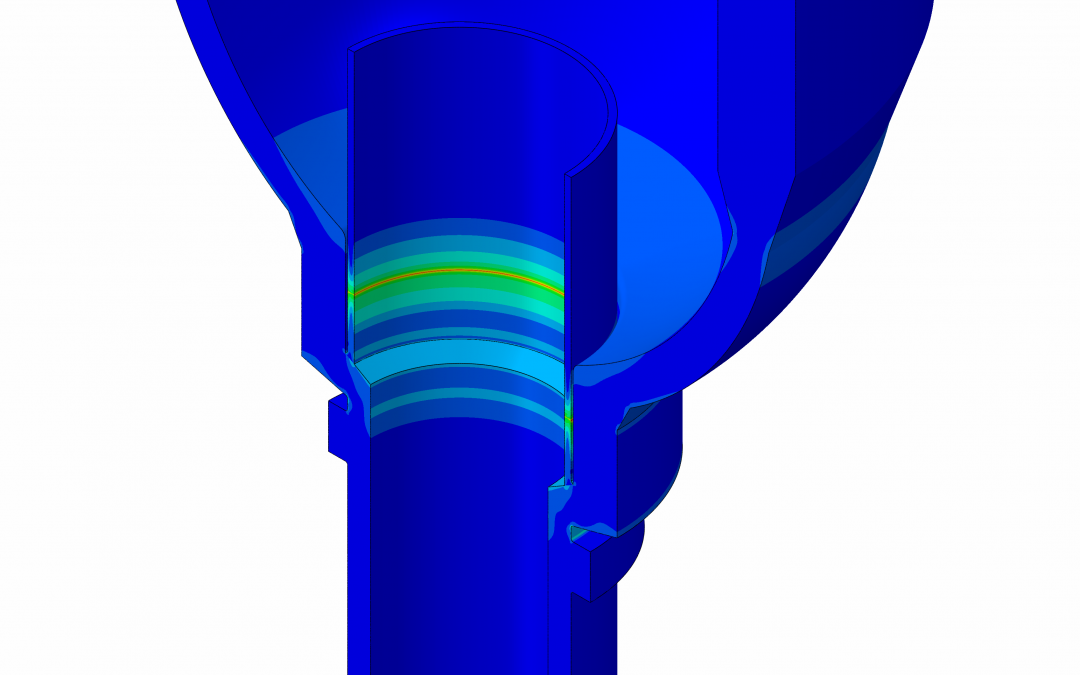

High temperature hydrogen attack (HTHA) is a significant risk to the operation of critical pieces of equipment in the refining industry. FEC were approached by a client after identifying HTHA in the head of a Feed Converter Exchanger of their Ammonia Plant. The...

by Sam Nicklin | Jun 25, 2020 | Projects

FEC recently completed the full mechanical design, independent verification, drafting, and registration of the SABRE Veto Vessel. The stainless steel vessel was designed for The University of Melbourne to facilitate the research into dark matter at the Stawell...

by Sam Nicklin | Mar 26, 2020 | Projects

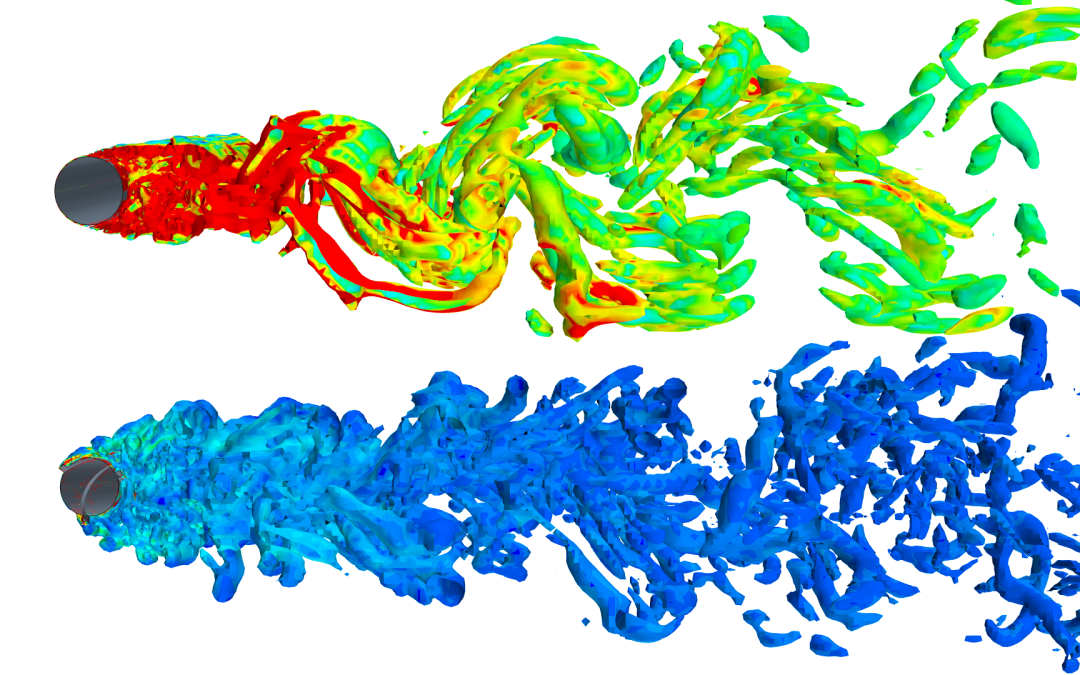

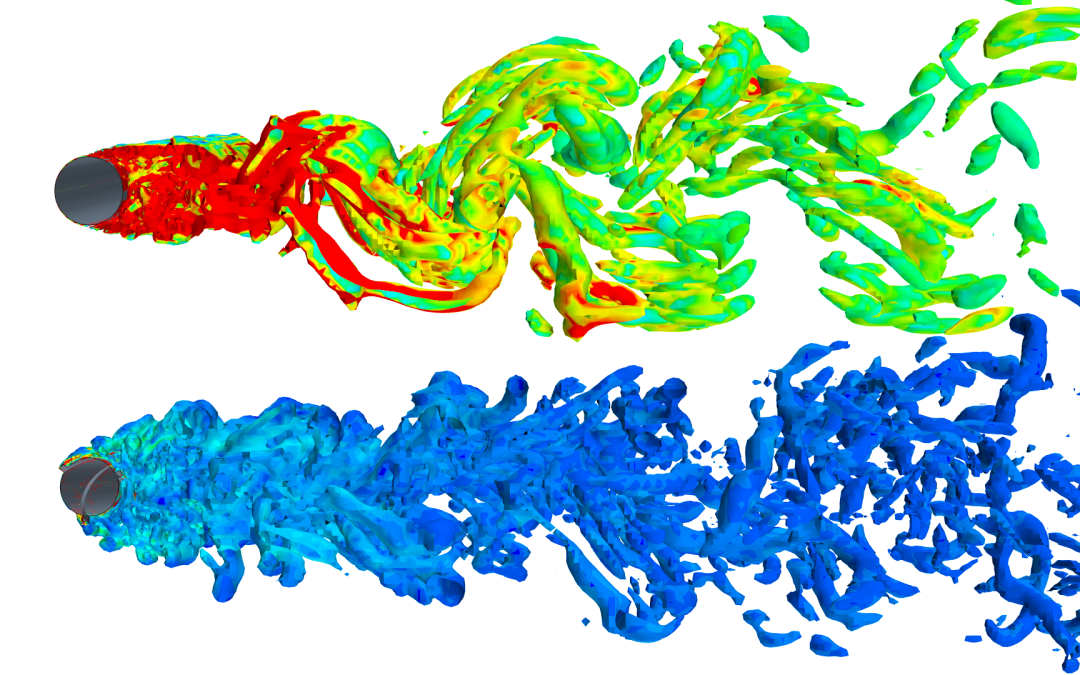

Thermowells, chimneys and stacks all represent the physical problem of a blunt body in crossflow. Depending on the diameter of the body and the velocity of the flow, they can be subject to the Von-Karman street shedding phenomenon, leading to Vortex-induced Vibrations...

by Sam Nicklin | Mar 20, 2020 | Projects

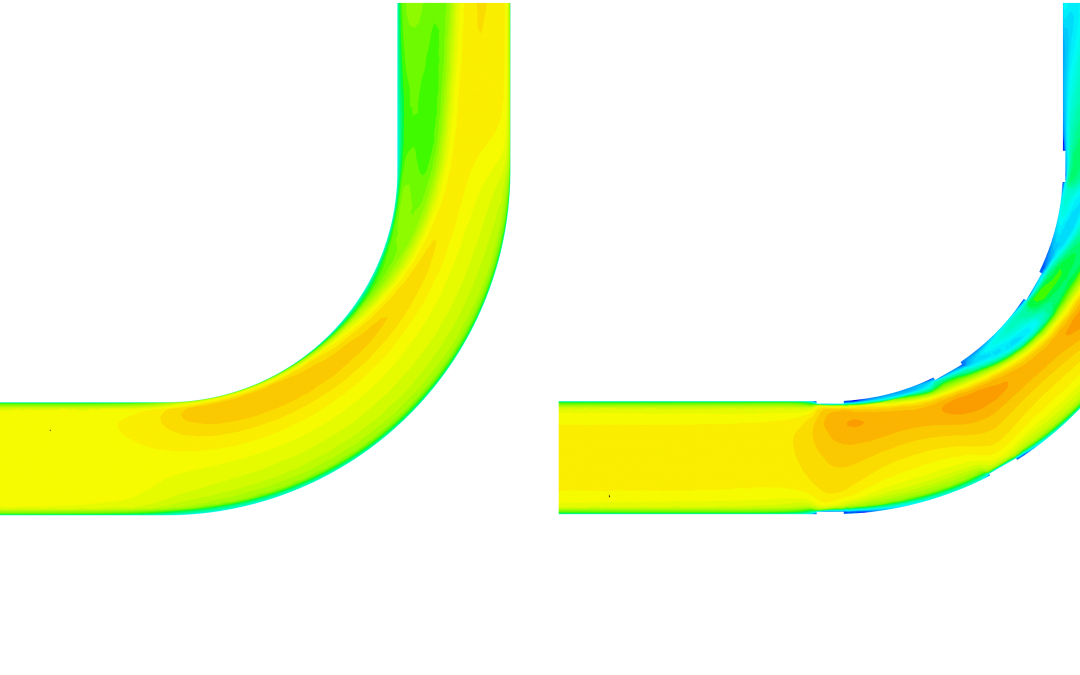

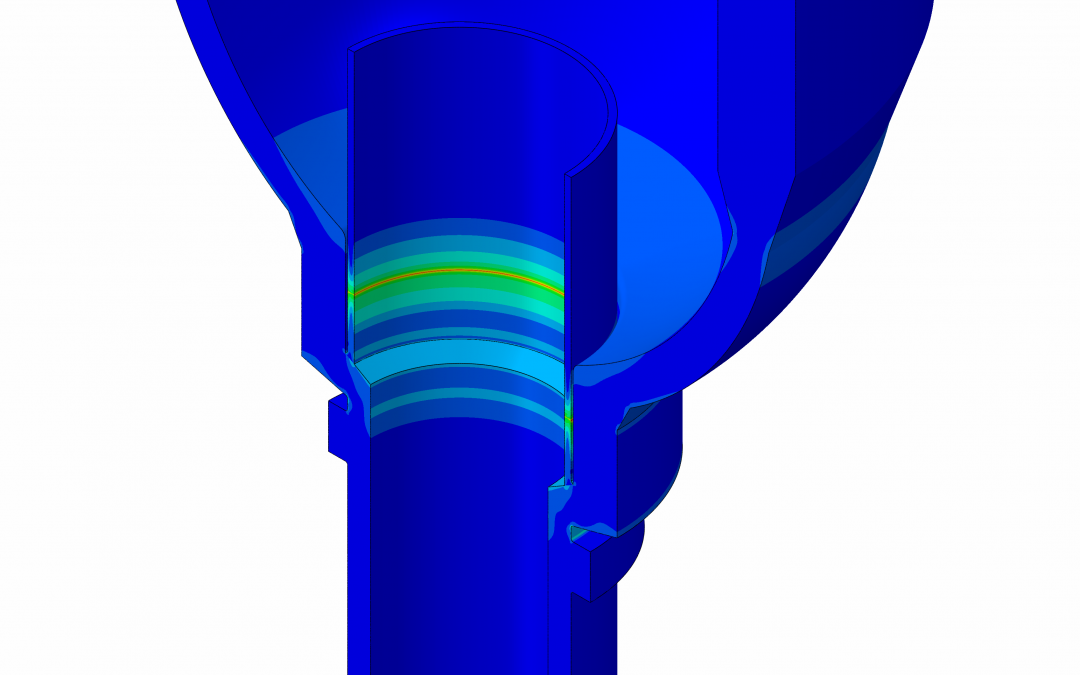

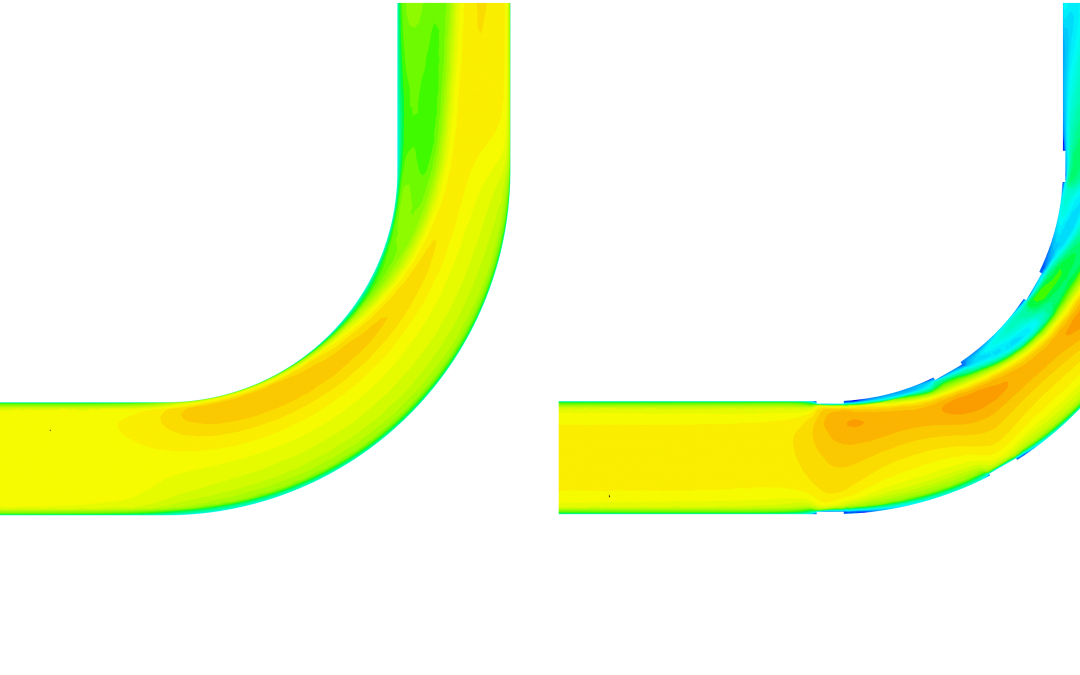

Pressure drop and other flow variables can be a crucial factor in certain industrial applications. The ability to simulate and analyse pressure distribution along the wetted volume enables the designers to minimize losses and to optimise the design. Comprehensive flow...

by Sam Nicklin | Jan 16, 2020 | Projects

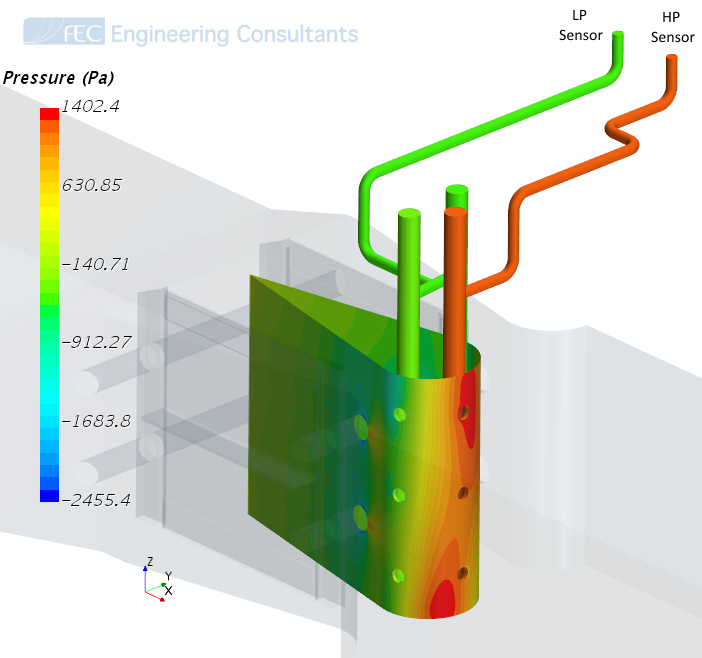

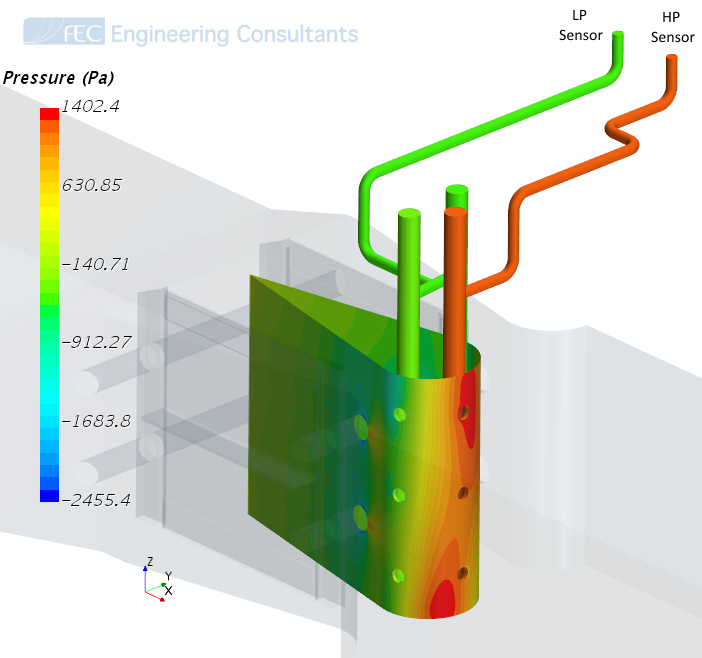

FEC were engaged to complete the computational fluid dynamics (CFD) analysis of the primary air flow meters in a fan duct. The duct supplies a mixture of pulverised coal and primary air to the furnace. The client was concerned about the accuracy and validity of the...