Projects

Hazer – First Hydrogen at CDP

FE Consultants (FEC) are proud to announce the success of our long-time client Hazer Group Ltd (Hazer) in producing first hydrogen and graphite from their Commercial Demonstration Plant (CDP) in Perth, Western Australia. The CDP takes Biogas from a water treatment...

read moreHigh Temperature Leak Box

High temperature hydrogen attack (HTHA) is a significant risk to the operation of critical pieces of equipment in the refining industry. FEC were approached by a client after identifying HTHA in the head of a Feed Converter Exchanger of their Ammonia Plant. The...

read moreSABRE Veto Vessel

FEC recently completed the full mechanical design, independent verification, drafting, and registration of the SABRE Veto Vessel. The stainless steel vessel was designed for The University of Melbourne to facilitate the research into dark matter at the Stawell...

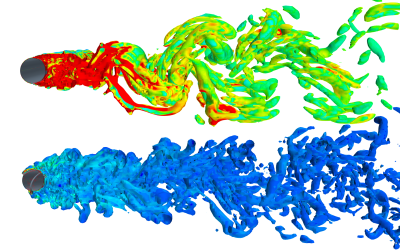

read moreVortex Induced Vibrations in Thermowell

Thermowells, chimneys and stacks all represent the physical problem of a blunt body in crossflow. Depending on the diameter of the body and the velocity of the flow, they can be subject to the Von-Karman street shedding phenomenon, leading to Vortex-induced Vibrations...

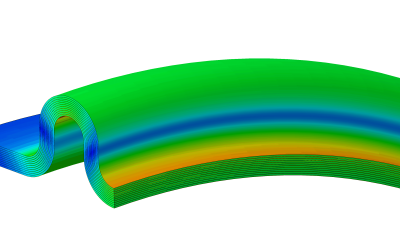

read moreFlow Simulation in Piping

Pressure drop and other flow variables can be a crucial factor in certain industrial applications. The ability to simulate and analyse pressure distribution along the wetted volume enables the designers to minimize losses and to optimise the design. Comprehensive flow...

read moreBoiler CFD

FEC were engaged to complete the computational fluid dynamics (CFD) analysis of the primary air flow meters in a fan duct. The duct supplies a mixture of pulverised coal and primary air to the furnace. The client was concerned about the accuracy and validity of the...

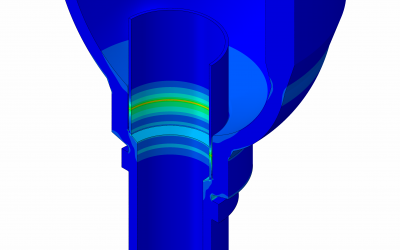

read moreBlowout Stopper Mechanical Design and Drafting

Since 2016, FEC has been working collaboratively with a client based in Houston to assist in engineering and drafting works for their product development. The products in development represent a significant advancement in Blowout Prevention (BOP) technology used in...

read moreThickener tank repair design

FEC completed the mechanical, structural, access and piping design for the entire repair sequence of 2 thickener tanks at a Queensland alumina refinery. At 22m in diameter and over 15m high, the replacement of the top strake presented several challenges. A common...

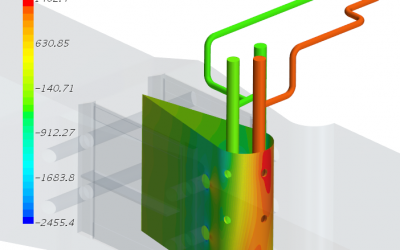

read moreHigh-Temperature Reactor Design

In 2018 FEC completed the mechanical design of two novel high-temperature reactor systems for the conversion of iron-ore and natural gas into hydrogen and synthetic graphite. Working with our client’s specialist chemical engineers, FEC progressed from a P&ID to a...

read moreCaustic line replacement

FEC completed the structural, mechanical and piping design for a caustic line replacement at a QLD alumina refinery. The scope of works required design development with relevant stakeholders and determination of the ideal route for site works, access restrictions and...

read moreFull structural, mechanical, and piping design of skid package

FEC completed the full structural, mechanical, and piping design, and detailed drafting for a dehydration package. The multi-disciplinary FEC team worked collaboratively with the client and end-user to iterate the design to their specifications and constraints....

read moreDetailed Design and Analysis for Rectangular Tank Subject to Internal Explosion Pressure

FEC complete detailed design and analysis for rectangular tank subject to internal explosion pressure. The project had a number of unique constraints which led to our client requiring a rectangular tank. As a first pass, we completed elastic stress analysis and...

read more7C8 Main Fractionator

FEC recently completed the design and drafting of a vessel section for a local fabricator. Working collectively with our client and the end user, the scope included design of the vessel, platforms, lifting, tailing, transport and temporary support during storage. The...

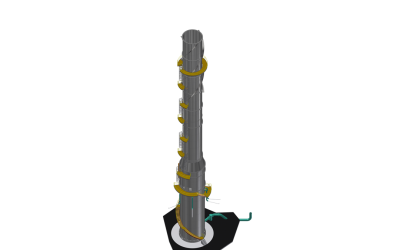

read moreAccess and Column Support Tower

FEC recently completed the design of an access and column support tower. Encompassing structural drafting and engineering design to AS4100; the tower was designed in a modular fashion for ease of road transport, ground assembly and tailing / lifting as a complete...

read moreFabrication Experience with Major APLNG Supplier

An engineer from FEC has completed a five-week secondment to a major fabricator based in Thailand. The experience provided both professional and personal development. The Thailand based company, has a long history of large scale steel fabrication projects. From...

read moreStress Corrosion Cracking on Turbine Rotor

FEC was approached by one of our clients who had experienced a turbine rotor failure due to stress corrosion cracking. Following the failure, a monitoring program for crack detection and growth was implemented. During the crack inspection program one rotor showed...

read moreFFS on Multi-ply Expansion Bellows

FEC was approached by one of our clients who had been supplied an expansion bellows in the repaired condition. During fabrication of a shell and tube heat exchanger, its laminated style expansion bellows was accidentally damaged in a grinding operation. Damage to the...

read moreAxial Load Capacity of Proprietary Buttress Thread

FEC was approached by one of our clients requiring verification of the axial load capacity for a proprietary developed buttress thread for use in well casing. The design was unique in that it required creating a flush joint for the casing as opposed to using the...

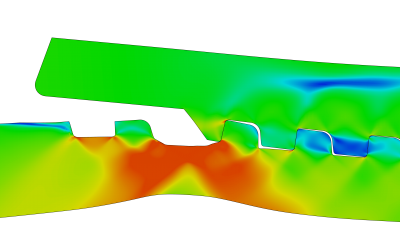

read moreReduced Nozzle Wear Rates via CFD

FEC was approached by one of our clients experiencing significant downtime and resultant costs caused by the regular failure of a nozzle and plug valve used in a thickener underflow application. The aim of the project was to determine whether planned geometry...

read moreDetailed Design of Macknade Mill Boiler Stack

The FEC designed Macknade Mill Stack was commissioned in June 2014. The stack operated effectively during the earlier steam trials, allowing adequate separation between the two feed boilers. One of the early concerns in the stack design was inadequate separation...

read moreHead Office (Brisbane)

ABN 30 161 215 372

PO Box 3083

Newstead, 4006,

Qld, Australia

14 Jordan Terrace,

Bowen Hills, 4006,

Qld, Australia

All of the content on this website is the property of FEC or used with permission from our clients. Reproduction or use of this content without express written permission from FE Consultants is prohibited.