Pressure Vessel and Tank Design

Being actively involved in the development of pressure vessel Standards and familiarity with fabrication, operation and regulations, FEC is positioned to deliver customer driven solutions for vessel design. We have design history with most of the local and international standards. Upon completion of any vessel design, the client is provided a comprehensive design report detailing the conclusions, assumptions and all calculations. Our experience has shown that designs must be comprehensive and also require traceability to allow for exhaustive verification, so as to comply with the various state authorities. Comprehensive documentation also aids in the future operation of the vessel should it be subject to fitness-for-service or re-rating requirements.

Services

AS1210, ASME VIII Division 1 and 2, EN13445, PD5500

- Pressure boundary design

- Tank floating roof

- Vortex shedding and frequency should be listed after environmental loading

- Re-rating

- Repaid

- Nozzle loading

- Custom flanges

- Supports

- Environmental loading

- Thermal stress analysis

- Fatigue

- Vortex shedding and frequency

- Tray supports

- Lifting lugs, davits and trunnions

- Tubesheets

Equipment Types

- Receivers

- Process Columns

- Heat Exchangers

- Vacuum Pans

- Boilers

- Separators

- Clarifiers

Job List

Design, drafting and verification of 106mm thick ASME VIII Division 1 vessel.

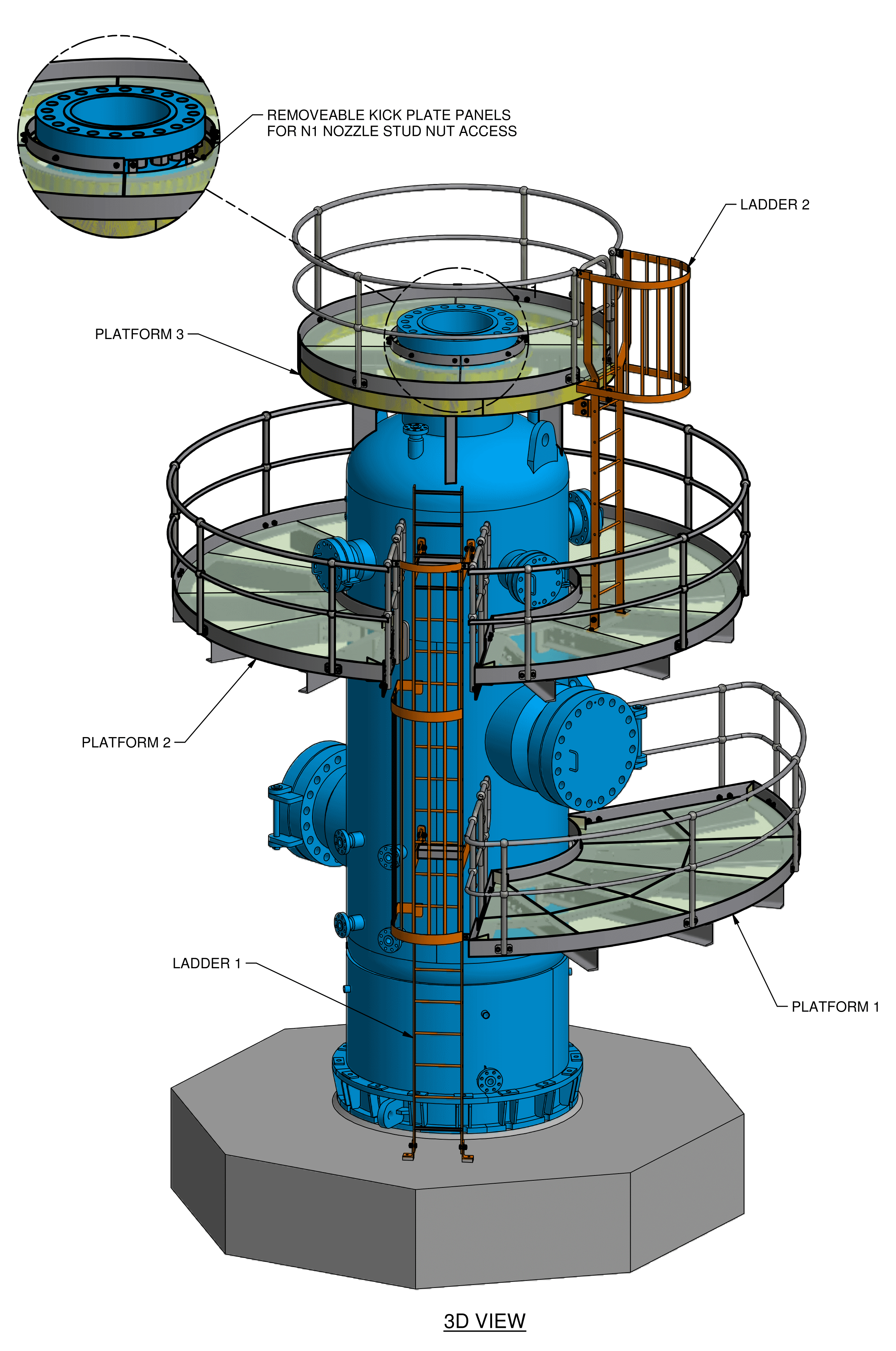

Complete engineering design to ASME Section VIII Division 1 for the 106mm thick vessel. Design conditions and material of construction required that the vessel be subject to impact testing and Post Weld Heat Treatment (PWHT). With a fabricated weight of 55,000kg and being 6,000mm high the design also included nozzle loads, lifting, environmental loads, platform structural design and compliance with AS1657. FEC produced detailed fabrication drawings using Autodesk Inventor to permit efficient fabrication, layout adjustment and clash detection. Relevant standards used in completion of the project were AS1170.0, AS1170.2, AS1170.4, ASME VIII Div. 1, AS1657 and AS4100.

Design, drafting and verification of 6 vessels.

Complete engineering design to AS1210, prepare fabrication drawings and an internal design verification. Ensure the engineering design meets the clients project specifications for wind, seismic and pressure equipment. Relevant standards AS1170.0, AS1170.2, AS1170.4, AS4458, AS1210 and AS3788.

Design, drafting and verification of a 600NB separator.

Complete engineering design to AS1210, prepare fabrication drawings and an internal design verification. Also review the acceptability of the vessel under published standard nozzle load tables.

Design, drafting and verification of bladder vessel.

Complete engineering design to AS1210 and prepare fabrication drawings based on a supplied datasheet. Complete wind and seismic loadings for the vessel with a platform mounted atop.

Head Office (Brisbane)

ABN 30 161 215 372

PO Box 3083

Newstead, 4006,

Qld, Australia

14 Jordan Terrace,

Bowen Hills, 4006,

Qld, Australia

All of the content on this website is the property of FEC or used with permission from our clients. Reproduction or use of this content without express written permission from FE Consultants is prohibited.