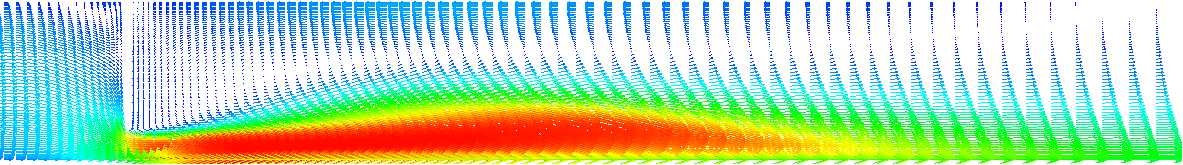

FEC was approached by one of our clients experiencing significant downtime and resultant costs caused by the regular failure of a nozzle and plug valve used in a thickener underflow application. The aim of the project was to determine whether planned geometry modifications to the nozzle would increase service life and prevent unscheduled maintenance. FEC undertook Computational Fluid Dynamics modelling of the existing geometry (benchmark) and reviewed several proposed solutions. The model used a steady state, two-phase flow field with the modified Tabakoff and Grant erosion model. The following models were reviewed:

- existing geometry;

- increased internal diameter and diverging entrance; and

- increased internal diameter and stepped entrance.

The predicted wear rates for all three models were developed and reviewed by FEC. For case 1, the stepped design allowed for a tangential flow with respect to the nozzle wall, which actually produced a low impact angle and low impact velocity.

The diverging nozzle directed the flow towards the valve wall which significantly increased the impact angle and concentrated wear. Wear rates were predicted to be 30 times greater than the original design.

By virtue of design, the nozzle and plug valve was a component with short service life. It had to be regularly maintained and occasionally resulted in emergency maintenance and loss of production. When the decision was made to improve the design, intuition suggested that the tapered modification would gently change the flow direction and reduce wear rates. The aim of the investigation was to evaluate the affect of these proposed changes on service life.

FEC we were able to provide our client with the following benefits:

- the evidence that the proposed modification would actually increase erosion rates;

- saved the installation costs including components, labour and downtime for a detrimental modification;

- prevented future emergency maintenance when the component failed; and

- the opportunity to complete an improved design.

The analysis found that the proposed geometry, which initially appeared superior to the existing, would cause premature shutdown of a major plant item. The use of CFD in the investigation of this problem enabled quick and efficient evaluation of proposals.