by FE Consultants | Dec 13, 2016 | Projects

FEC was approached by one of our clients experiencing significant downtime and resultant costs caused by the regular failure of a nozzle and plug valve used in a thickener underflow application. The aim of the project was to determine whether planned geometry...

by FE Consultants | Dec 7, 2016 | Projects

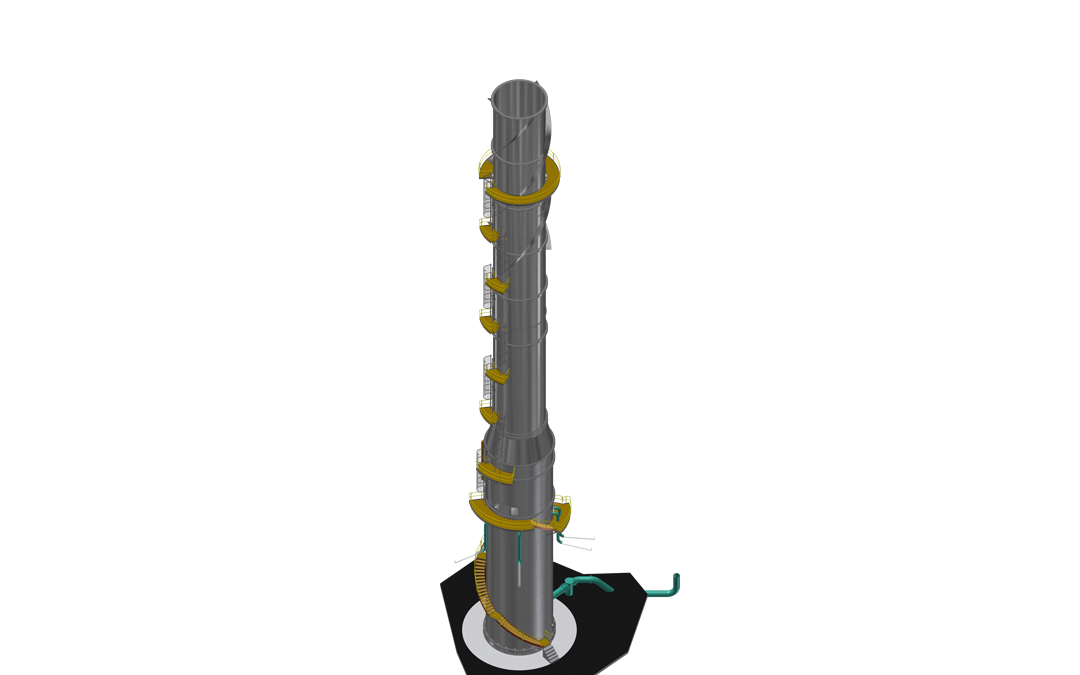

The FEC designed Macknade Mill Stack was commissioned in June 2014. The stack operated effectively during the earlier steam trials, allowing adequate separation between the two feed boilers. One of the early concerns in the stack design was inadequate separation...